MODULAR/BAILEY BRIDGE

Bailey Bridge

Bailey Bridge was conceptualized and designed by Sir Donald Bailey, UK in 1941. These bridges were extensively used during the Second World War.The Govt. of India got these designs, drawings and specifications from the Govt. of UK through Transfer of Technology (TOT). The seal-holding authority of these documents is the Controllerate of Quality Assurance (Engineering Equipment) (CQA(EE)), DGQA, Ministry of Defence, Govt. of India.

Features Of Bailey Bridge

- Design based on single-lane

- Modular concept – in modules of 10 ft. upto 200 ft. in a single unsupported span

- Modules comprise Panels, Transoms, Deck Units, Clamps, Nuts, Bolts etc. in certain proportions to constitute a bridge

- Rows of Panels form the two main girders of the bridge

- Panels are connected end to end with pins made of high strength alloy steel duly heat-treated

- Connected by Transoms as cross members which carry the bridge roadway

- Load carrying capacity can be increased with addition of extra panels and corresponding set of components

- Bridge construction is described by the number of trusses and storeys forming the main girder

- Various combinations of girders are worked out based on load class and span of the bridge

- Ends of each truss of bridge girders are attached with the End Posts resting on bearings

Technical Specification

- High yield strength Micro-Alloy steel is used for manufacture of panel, transom, raker, stiffeners of steel deck etc.

- Panel pins are manufactured from special quality of Alloy Steel duly heat-treated to give minimum yield strength of 50 TSI and minimum izod 40 ft-lb.

- Deck units are fabricated from anti-skid chequered plates.

- The section of Transom is joist of high tensile structural steel.

- All fabricated parts are given 2 coats of Red Oxide Zinc Chromate primer to IS:2074 followed by 2 coats of Olive Green paint to IS:8982.

- All fastening parts, viz., Panel Pin, Bolts, Nuts etc. are electro-zinc plated.

- Based on specific requirements of customers, the bridge components can be supplied in galvanized condition using the process of Hot Dip Galvanizing. Components are protected against corrosion by a zinc coating applied by dipping them in a bath of molten zinc at about 450oC.

Make Your Project COME TRUE

Classification of Bailey Bridge

Bailey Bridges are classified based on width of carriageway (roadway)

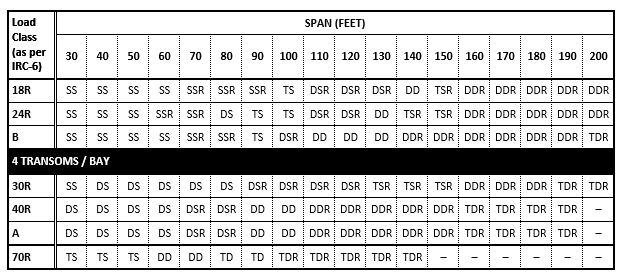

LOAD-vs-SPAN CHART

The construction of a Bailey Bridge is determined based on the load class. Based on the load classes, suitable constructions are determined as per the following Load-vs-Span nomograms.

Table-1 : Recommended Constructions For Steel Deck STANDARD WIDTH Bailey Type Expandable Bridges

Table-2 : Recommended Constructions For Steel Deck EXTRA WIDE Bailey Type Expandable Bridges